Refractory Brick

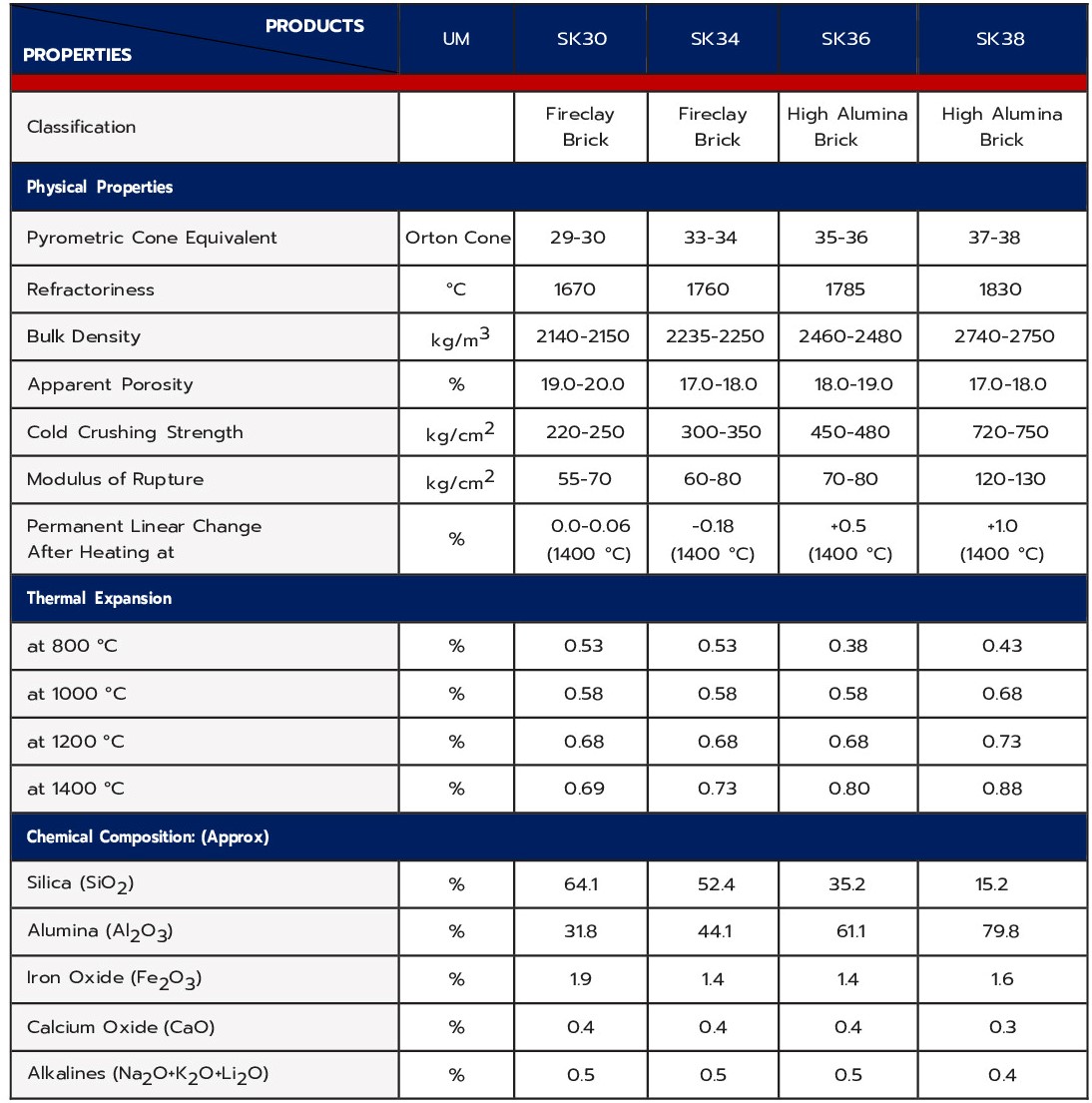

At BST, we are manufacturer of Fireclay & High Alumina brick. Fireclay bricks mainly contain less than 45% Alumina content while High Alumina bricks contain more than 45% Alumina.

Properties

- Alumina content in fireclay bricks approximately 28-45% are classified to Medium-duty Fireclay Brick and super-duty fireclay brick

- Alumina content in fireclay bricks between about 10-28% are classified to low alumina fireclay bricks.

- Good thermal shock and spalling resistance.

- Good volume stability at high temperature.

- High mechanical strength.

- Alumina content in high Alumina bricks from 45% to 95% and service temperature up to 1900 ◦ C

- Excellent corrosion resistance to neutral slag and meta penetration resistance at high liquid temperature.

- Improved thermal shock and corrosion resistance at high temperature.

- High density, high mechanical strength and good volume stability at high temperature.

Applications

- Furnace construction

- Blast furnace/ Hot blast stove

- Steel foundries

- Furnace in the nonferrous metal industry

- Coke ovens and gas furnace

- Glass industry

- Cement Industry

- Safety lining of ladle

- Backup lining of boiler

- Good for reheating furnace such as anchor brick and burner block

- Transition and cooling zone of rotary cement kiln, lime shaft kiln, etc.

- Bottom and door foundry air furnace and side wall of aluminum refining melting furnace, etc.